Applications

10% off for first time customers

Applications

Restoration

Remedial Cleaning

Dry ice blasting is highly effective for cleaning brickwork and stone surfaces, making it an ideal solution for maintaining the appearance and integrity of buildings, monuments, and other structures. This method gently removes contaminants such as dirt, soot, and biological growths (e.g., moss, algae) without damaging the underlying materials. It’s especially useful for historic preservation projects where maintaining the original condition of the stone or brickwork is crucial.

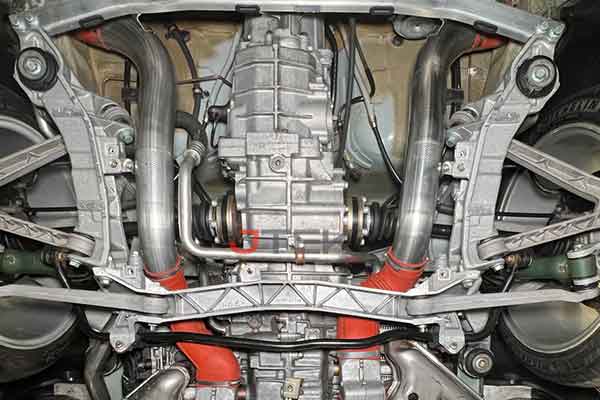

Automotive

The automotive sector reaps significant advantages from dry ice blasting, which effectively cleans parts and molds by eliminating contaminants such as grease, oil, and carbon deposits while preserving delicate surfaces. This technique is particularly suited for maintaining engines, transmissions, and various automotive components, ensuring their optimal performance and extending their lifespan.

Industrial Cleaning

Dry ice blasting is perfect for cleaning industrial machinery and equipment. It efficiently removes grease, oil, and built-up grime that can affect machine performance. This method is particularly beneficial for maintaining equipment in manufacturing plants, where cleanliness directly impacts efficiency and safety.

Food Processing

In the food processing industry, maintaining high levels of cleanliness is crucial. Dry ice blasting sanitises equipment and surfaces without the use of chemicals, ensuring compliance with strict hygiene standards. This method is effective in removing residues such as fats, proteins, and carbohydrates, providing a thorough clean that helps prevent contamination.

Marine Antifouling Removal

Marine vessels are often affected by biofouling, the accumulation of barnacles, algae, and other organisms on the hull. Dry ice blasting provides an efficient and environmentally friendly method to remove these organisms, helping to maintain the vessel’s performance and fuel efficiency. This process is safe for the hull materials and does not involve toxic chemicals, making it an ideal choice for marine applications.

Click to Call us (On Mobile)